Custom Paper Bags

Custom Paper Bags that make every detail look sharp, thoughtful, and totally on brand.

Paper Bags Offerings

Good Luck Floral Bag

Citrus Kraft Bag

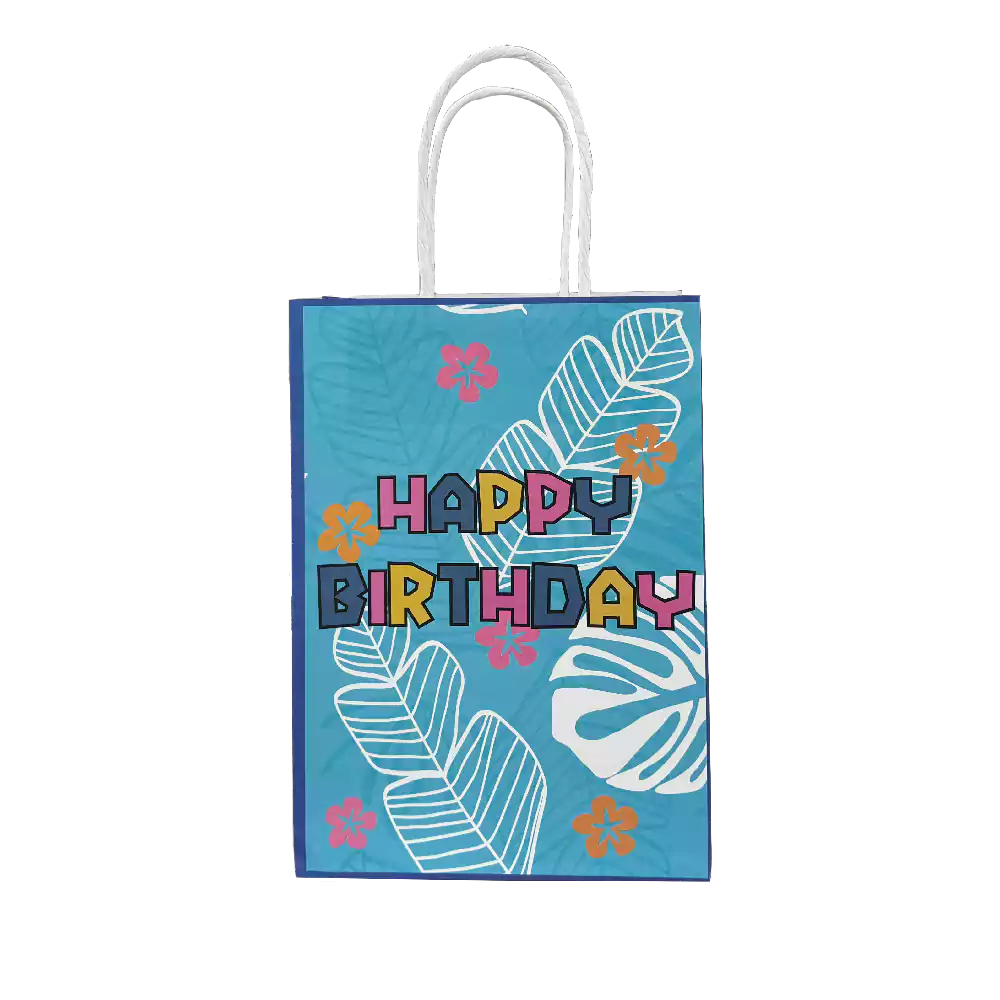

Birthday Celebration Bag

Bunny Party Gift Bag

Black Trim Bag

Matte Paper Bag

Luxury Shopping Bag

Kraft Paper Bag

Let’s Build Your Box Together!

90% clients confirm quality within 3 days after sampling.

Contact us for your Scenario

Benefits from Cooperating with PackWo

Green Inside and Out

We offer recyclable and FSC-certified options to help you build a sustainable brand.

From Us to You

No middlemen. You get better prices and better quality, straight from our factory.

Start Fast, Grow Fastert

You’ll get your samples fast. 90% clients confirm quality within 3 days, so you can save time and launch sooner.

Your Box, Your Way

Customize the size, shape, and style to fit your product and match your brand perfectly.

Materials and Options for Paper Bags

From Design to Delivery – Everything Handled

Custom Design

We help turn your ideas into real packaging. Send us your logo or concept—we’ll guide you through the design.

In-House Production

All boxes are made in our own factory. From material cutting to printing, everything is done under one roof.

3-Step QC

We follow a strict 3-step quality check process to ensure your boxes look great and arrive damage-free.

Global Shipping

We deliver worldwide in as fast as 15 days. On time, secure, and fully trackable.

Your Concerns, Solved in 30 Seconds

Is your packaging eco-friendly? Do you support sustainable materials?

Yes, we offer eco-friendly packaging options including FSC-certified paper, recycled materials, and biodegradable molded pulp. We’re committed to helping your brand go greener.

What payment methods do you accept?

We accept bank wire transfers and support a deposit + balance payment model.

Flexible payment arrangements can be discussed based on your order.

How much budget do I need to start custom packaging?

The minimum budget to start is around $350, based on basic paper box packaging.

This includes printing, lamination, and gluing.

Luxury gift boxes are not included at this price. If you’re just getting started, this is a great entry point for custom packaging.

Are you a factory? Where do you produce? Is the quality reliable?

Yes, we’re a direct factory based in Foshan, Guangdong, China.

We support online factory inspections, so you can see our process firsthand.

Our team carefully controls color accuracy during printing with multiple adjustments and checks.

Every order is thoroughly inspected before shipping to ensure it meets our quality standards.

My current packaging doesn’t look high-end or eco-friendly. Can you help upgrade it?

Of course! Just send us the type of packaging you have in mind, and we’ll help design it for you.

We also have FSC certification, so we can offer eco-friendly materials to help you build a sustainable and premium brand image.

Can you provide free samples?

Yes, we can provide samples. You’ll just need to cover the international shipping cost. For custom samples, we require a deposit before production and delivery. However, once you place a full order, the sample cost will be fully refunded.

Can you help design the packaging?

Yes, no problem! At Packwo, our design team can help create packaging that fits your brand and makes your products look more professional and eye-catching.

Why is the color of the final product different from the sample?

Color variation during printing is normal in the industry and can be influenced by several factors:

- Human perception – Different people see colors slightly differently.

- Paper differences – Paper from different batches may react to temperature and humidity, causing slight changes in how colors appear.

- Finishing process – Most papers are coated with a film, and different types of lamination can affect the final color look.

Still have questions?

Get in touch for a consolution

Let’s talk packaging. Whether you need a quote, advice, or just want to explore ideas, we’re ready when you are.

Contact usGet your first order

FSC-certified materials with gold foil stamping • 0 packaging return rate in EU