If you’re ordering custom mailer boxes for the first time, pricing can feel like a mystery. Some quotes look affordable, others feel way too high, and without context, it’s hard to know what’s fair. The cost of custom mailer boxes isn’t one-size-fits-all. It depends on what you’re making, how many you need, and the kind of first impression you want to leave.

Size, material, printing, and quantity all play a role. A small one-color box ordered in bulk will cost a lot less per unit than a full-color design with custom inserts or a high-end finish. It also matters how your custom boxes are shipped and stored. Some are supplied flat, which cuts down on delivery costs and makes them easier to manage behind the scenes.

In this guide, we’ll break down what goes into the price, share real-world examples, and show how businesses can get the look they want without overspending. If you’re investing in packaging that reflects your brand and keeps customers coming back, this will help you make a smarter call.

So, read on to find out what really drives the cost and finally stop guessing if your quote includes invisible gold foil or just the logo you uploaded yesterday.

Key Factors That Influence Cost

Box size is only one part of the equation. What you choose for materials, printing, and order volume plays a big role in how much each unit costs and how well your packaging fits your budget.

- Box size and style

Larger boxes or complex box designs with tuck flaps, tabs, or custom inserts use more material and take longer to produce. That pushes the price up compared to smaller, simpler styles.

- Quantity

Ordering a higher quantity brings your per-unit cost down because it spreads out the setup and production time. If you’re printing 250 or 5,000 units, the machines are already running, so the extra volume doesn’t add much in labor or material costs. It’s a simple way to get more value from your custom packaging, especially when you plan ahead or stock for seasonal spikes. - Materials

Standard corrugated cardboard is usually the most cost-effective and sturdy. Premium picks like white coated E flute or soft-touch paper finishes will cost more but offer a more polished feel.

- Finishes and features

Special touches like matte or gloss coatings, foil accents, or embossed details help elevate the look of your custom printed boxes, but they also raise the price. If you’re going for a fully customisable experience, keep in mind that extras like branded tape, printed interiors, or soft-touch textures all add to the final cost. They’re worth it when your packaging plays a big role in the unboxing experience or retail presentation, but they aren’t always necessary for every shipment.

- Printing

A simple one-color logo is cheaper than full-color graphics or bright colours that cover the entire box. Complex custom printed surfaces take more time and ink to produce.

- Shipping and Storage

Boxes that are supplied flat ship more efficiently and are easier to store in bulk. That saves you on freight costs and warehouse space, especially if you’re running a high-volume e-commerce business. Flat-packed postal boxes also simplify inventory handling, since you can keep more on hand without cluttering your shelves. When you’re ready to use them, they’re easy to fold and pack without slowing down your fulfillment line.

Making smart choices in these areas helps you control cost while keeping your custom packaging true to your brand.

Pro Tip: We recommend ordering at least a few hundred units if you’ve already finalized your box design. You’ll get a much better price per box, save on shipping, and avoid the stress of running low during peak weeks. It’s one of the easiest ways to make your custom packaging more cost effective without changing a thing.

Average Pricing Breakdown by Type

If you’re trying to figure out how much your custom mailing boxes might cost, this table gives you a general idea based on size, print type, and order volume. Prices vary depending on the setup, materials, and features, but here’s a solid starting point:

| Box Type | Price Range (Per Unit) | Details |

| Basic Logo Print | $0.60 – $1.20 | Small mailer boxes, one-color print, flat-packed |

| Full-Color Mailer Box | $1.50 – $2.80 | CMYK custom printed boxes, moderate size, E-flute |

| Premium Custom Design | $3.00 – $5.50+ | High-end packaging, custom cutouts, luxury finish |

| Small-Batch Starter Packs | $2.00 – $3.00 | Low quantity, fast turnaround, ideal for testing |

Here’s an example:

A subscription box brand ordering 1,000 mid-sized custom printed boxes with a full-color wrap might pay around $2.10 per box. On the other hand, a smaller company testing just 100 units could see a price closer to $3.50 each, since the cost of printing and setup isn’t spread across as many boxes.

Understanding where your needs fall in this price range can help you plan smarter. You might be building your first line of cardboard boxes, or you could be scaling up an existing batch of branded packaging. Either way, knowing the cost benchmarks helps you make clearer decisions.

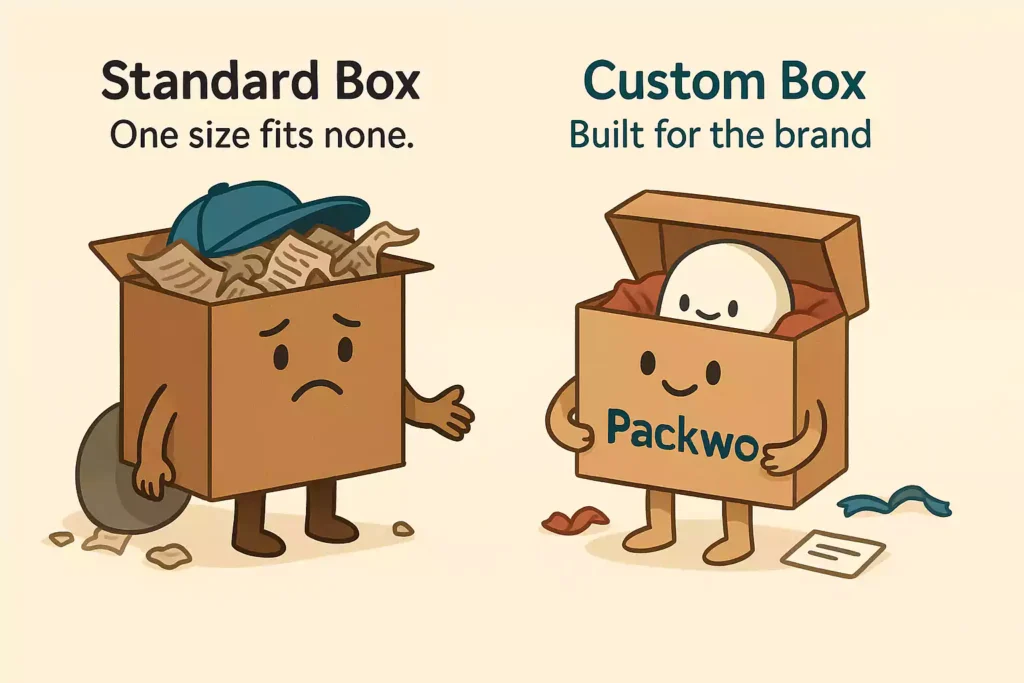

Print & Design: What Affects the Price?

The design side of your box, including how it looks, where your logo goes, and how much you print, can have just as much impact on price as the box itself.

If you’re going with a simple, single-color logo on one panel, your costs stay low. Add more colour, full-wrap designs, or complex graphics, and the price rises. The more surface area you want to cover and the more sides you want printed, the more ink, time, and setup it takes.

Traditional offset printing uses plates, which means extra setup and cost if you change designs often. Digital print skips that step entirely and is great for short runs or frequent updates. There are no extra fees for new templates, which keeps things simpler.

Your file type and layout also matter. High-resolution artwork, clear file formatting, and smart positioning of your brand message help avoid reprints or prepress delays. Uploading clean graphics in vector format ensures your final box comes out looking as sharp as your mockup.

To keep costs balanced, focus your custom printed design on one or two high-impact areas. That could be a bold top panel, branded sides, or a surprise interior detail that still feels true to your brand.

If you’re looking for smart design ideas, layout examples, and practical branding tips, Shopify’s packaging guide pairs perfectly with what we’ve covered here.

Add-Ons That Can Raise (or Lower) Your Total Cost

Once your box is sized and printed, the next price factor is what goes into the extras. Some features boost the look and protection of your packaging, while others help you keep things cheaper without cutting quality.

- Add-ons like tuck locks, inserts, or inside prints give a more finished feel but come at a higher price.

- Swapping full artwork for a solid color and a clean logo keeps your box simple and cost effective.

- Premium finishes such as embossing, foil, or spot UV are great for gifting but belong in the high-end range.

- You can often skip loose fill by designing a snug-fitting box that secures the product in place.

- Boxes made from E-flute give you sturdy support without adding bulk or weight.

- Match the finish to the occasion. Go foldable and plain for standard shipping, then switch to gloss or texture when more impact matters.

There are always more ways to adjust the box than most people think. What matters is choosing the right ones for your product and your budget.

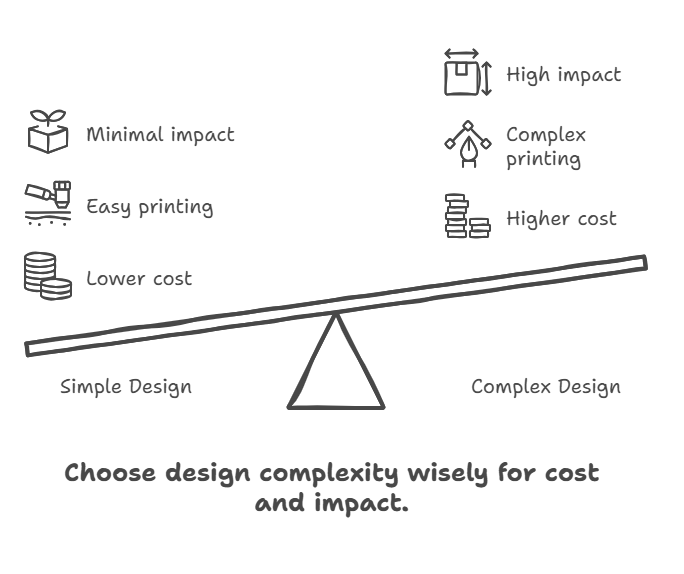

Cost-Saving Tips Without Sacrificing Quality

You don’t have to cut quality to control costs. There are small, strategic choices that help you save money while keeping your packaging on-brand and dependable.

Start by ordering in larger quantities when you can. A higher purchase volume brings down your per-unit pricing and keeps things running smoothly when orders pick up. You can also create flexible box designs that work across multiple products, so you’re not paying for new layouts every time something changes.

If you want to lower printing costs without losing visual appeal, use one strong side of the box for your branding instead of full coverage. It still makes a clean impression and keeps the design focused. Choosing standard cardboard sizes also helps. Pre-sized boxes are often more cost effective than custom dimensions, and they’ll usually ship faster, too.

Avoid using cheaper materials that weaken the structure of your box. A few cents saved up front can lead to damage, delays, and returns, none of which help your product or your business. Solid materials that hold up in transit are still the better investment.

Why It’s Worth the Investment

Paying a little more for well-designed product packaging can have a bigger impact than most people expect. A sturdy, great-looking box shows up looking sharp and holds everything together from the warehouse to the doorstep. That kind of care doesn’t go unnoticed.

Your custom mailing boxes are often the first physical part of your brand a customer interacts with. They set the tone, tell your story, and shape the unboxing experience long before the product is touched. When that first impression lands well, it sticks. In a crowded market, impressions count.

For growing e-commerce businesses, packaging is one of the easiest ways to stand out without adding more work to your plate. Thoughtfully designed printed postal boxes speak volumes about your brand and show customers you care from the moment their order arrives.

That kind of experience gets remembered, shared, and talked about. And the better your box is delivered, the more confident your customer feels about what’s inside.

Pro Tip: We recommend treating your box like part of the product. When your custom mailing box looks and feels solid, it builds trust right away and sets the tone for the unboxing experience before the product is even touched.

On A Final Note:

If you’ve made it this far, you’ve got a solid handle on what goes into the cost of custom mailer boxes and how to make smarter choices for your company without overthinking every detail. Size, materials, print, and quantity all play a part, but the goal is simple: get the right fit for your product and your budget.

Understanding the real custom printed boxes cost helps you make smarter packaging decisions without overspending or overordering. It’s all about making choices that feel right for your brand, your timeline, and how you work behind the scenes.

Ready to take the next step? You can upload your artwork, explore templates, or start building your mailer boxes right from our website. Add your picks to the basket, get pricing help, or request a sample to see how it looks before delivery.

We’ve made it easy to go from idea to a box that works. You’re just a few clicks away.