Choosing the right mailer box materials plays a bigger role than most people think. It impacts how your product survives the shipping journey, how your packaging materials support your branding, and how confidently customers feel when they open the box.

The material has to protect items, look good, and keep your shipping costs in check, all at the same time.

And if you pick wrong, you might end up spending more patching things up than delivering value. At PackWo, we’ve seen it happen over a dozen times. So, if you’d like to get it right the first time, do yourself a favor and stick to this page till the end. We specifically wrote this for you so you won’t have a rookie story to tell.

Start With Your Packaging Goals

Before choosing any material, you need to get crystal clear on what your packaging needs actually are. That starts with what you’re shipping and who you’re shipping it to.

If you’re sending fragile items across the country, you’ll need cushioning and durability to keep your customers happy.

Lightweight goods, like folded clothing or printed materials, often need less structure but still benefit from a clean, consistent presentation. And products with a long shipping route need more protection than ones heading just a few zip codes over.

But it doesn’t stop at logistics (even though that’s what a lot of people only care about). Your choice of material says a lot about your brand. If you want to create a lasting impression with a premium feel, consider using a sturdy matte finish with layered structure.

For eco-conscious brands, we recommend kraft paper, recycled corrugated cardboard, or molded pulp, which is strong enough to handle shipping and light enough for our lovely planet Earth.

Set the tone early. Clear goals lead to smarter packaging decisions that hit both function and aesthetics.

Pro Tip: We recommend checking your product return data before choosing materials. If you're seeing complaints about damage, chances are your packaging needs an upgrade. Choosing the right mailer box materials helps reduce returns, protect your products, and keep your customers happy.

Common Mailer Box Materials Explained

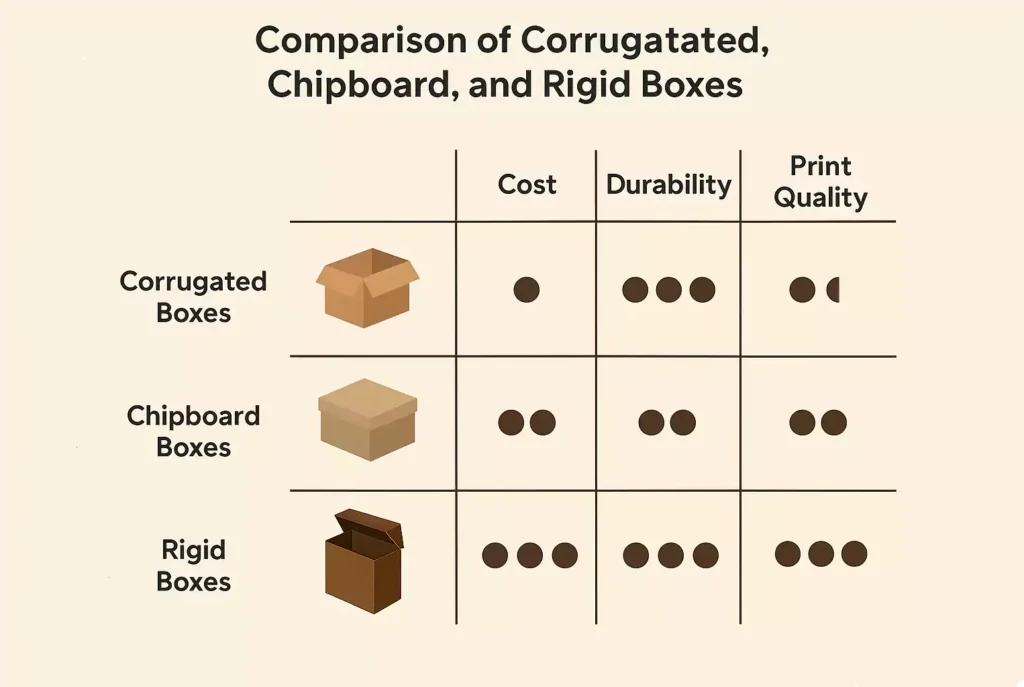

Let’s break down the most commonly used mailer box materials so you can make an informed decision. Each one has different strengths when it comes to shipping, protecting items, and delivering a strong unboxing experience without blowing your budget.

Corrugated Cardboard (The Most Common Option)

Corrugated cardboard boxes are a staple in e-commerce because they strike the perfect balance between affordability and durability, especially when you’re shipping at scale.

It’s strong, affordable, and made to handle everything from rough shipping routes to stacked warehouse storage.

It’s made up of fluted inner layers sandwiched between flat sheets, which gives it excellent durability without too much weight. You’ll usually see E-flute, which is slim and great for printing and lighter products.

Also, there’s B-flute, the thicker, better option for heavier items and fragile items. These variations allow you to match the level of protection with your product’s specific needs.

For basic, heavy-duty shipping needs, RSC boxes (regular slotted containers) offer a reliable, cost-effective option that works well with automated packing lines and common sealing methods.

This material is widely used in standard shipping boxes, corrugated mailer boxes, and retail-ready packaging. It handles most shipping materials like tape, labels, or stickers with no fuss, and it’s cost-efficient for bulk orders. Corrugated boxes get their strength from fluted inner layers that sit between flat liners, a design that’s been the backbone of secure packaging for decades according to the Fibre Box Association.

If you’re dealing with high-volume orders or need something that works across the board, corrugated boxes are a solid choice. Many corrugated cardboard boxes are made from recycled content, making them both durable and environmentally friendly for brands focused on sustainable packaging.

Chipboard or Paperboard (Lightweight and Low-Cost)

If you’re sending out promotional materials, subscription inserts, or lightweight gift boxes, chipboard is a practical pick. It’s thinner than corrugated cardboard, made from compressed recycled paper, and often used when packaging needs to look good without carrying much weight.

This lower cost material works well for cosmetics, stationery, and small accessories. It prints cleanly and folds neatly, which makes it great for branded presentation pieces where style matters more than strength.

That said, this material isn’t built to protect fragile or heavy items in transit. Use it when looks come first and protection comes second, think product sleeves, marketing kits, or lightweight box wraps.

Rigid Board (For Premium Brands)

When your packaging needs to feel more like a gift than a shipment, rigid board is the material to reach for. It’s thick, sturdy, and built to impress. You’ll find it in gift boxes, custom printed mailer boxes, and high-end product kits that aim to create a lasting impression from the very first touch.

Rigid boxes are often finished in premium white or wrapped with printed paper to match your brand identity. They’re the go-to for luxury items, influencer kits, and curated subscription boxes where presentation carries weight.

If you’re building a premium experience, this is the material that turns a simple delivery into a moment your customers remember.

If you’d like a bit of reminder later on, you can save this image to your gallery to remind you of the difference:

How Material Thickness Affects Protection and Cost

Material thickness plays a huge role in how well your mailer box performs in the real world. Thicker boards provide more structure and better resistance to drops, stacking, and general handling stress, especially important when you’re shipping fragile items like glassware or electronics.

But if you’re dealing with heavy items, we recommend stepping up from standard E-flute to something thicker like B-flute or even double-wall corrugated. It adds cost, but it also comes with peace of mind. Material thickness directly affects durability, and getting it wrong means risking product damage, returns, and unhappy customers. Choosing the right corrugated material, especially for fragile shipments, can prevent breakage and dramatically reduce return rates.

For added protection, consider cushioning materials like tissue paper, air pillows, or kraft void fill. These low-cost additions absorb shock inside the box and help keep your product in place, especially during long-haul transit.

A stronger material will go above and beyond to protect your product and your brand’s reputation.

Customization and Branding Considerations

Not all mailer box materials handle customization the same way, and this is where your printing process matters. If your brand depends on visuals that pop like vibrant graphics, bold logos, or crisp product images, you’ll want a surface that holds ink well and gives you a clean finish.

We recommend choosing a corrugated box with a white surface as it provides a smooth base for vibrant printing and detailed artwork. Using high quality materials not only improves print performance but also gives your packaging a more polished, premium feel that customers associate with trustworthy brands.

Custom printed mailer boxes made from white-coated corrugated or rigid board tend to deliver the best results. These materials offer smooth surfaces for HD print, rich color saturation, and options like matte finishes or soft-touch coatings. They also support clean lines and detailed artwork placement that elevate your brand recognition with every unboxing.

For brands trying to stay sustainable, we recommend soy-based inks instead of petroleum-based alternatives. They’re non-toxic, safer for the environment, and don’t compromise on print clarity.

You’ll also need to factor in printing plates for large offset runs or use digital printing for shorter batches and quicker turnaround. Either way, the material you choose has to match the quality you expect your custom boxes to deliver.

Sustainability Matters (If It Aligns With Your Brand)

For brands that want to make a smaller impact on the planet, eco friendly packaging materials are more available than ever. Many mailer box materials come in environmentally conscious options like recycled corrugated cardboard, FSC-certified kraft, or biodegradable paperboard, all of which offer that clean, natural look that resonates with today’s conscious shoppers.

| Material | Eco Benefit | Best Use Case |

| Recycled Corrugated Cardboard | Made from post-consumer fiber, recyclable again | E-commerce, shipping boxes |

| FSC-Certified Kraft | Responsibly sourced raw materials | Rustic or natural-looking boxes |

| Biodegradable Paperboard | Breaks down without harming the environment | Light retail, promotional kits |

We recommend boxes that are shipped flat whenever possible. It cuts down storage space, lowers freight costs, and helps reduce your brand’s carbon footprint. Fewer trucks, fewer trips, fewer emissions.

And yes, eco friendly packaging doesn’t mean cutting corners. Just make sure your materials still protect your product and deliver a solid unboxing experience. Green only works when it performs, so always choose suppliers who are transparent about the raw materials they use.

Cost Breakdown by Material Type

Here’s the cost breakdown by material type. This quick comparison helps you decide what makes sense for your business, if you’re launching new boxes or trying to save money without compromising on quality.

Each material serves a different need. Choose based on how your product will be handled, the type of customer experience you want to deliver, and your budget goals.

Pro Tip: We recommend matching your packaging material to both your product’s weight and your brand goals. For example, corrugated cardboard is ideal if you’re shipping heavier items and want durability without breaking the bank. But if you’re focused on luxury or high-end presentation, investing in rigid board gives you that extra edge that customers remember.

Choosing the Right Material Based on Your Product

No two products are the same, and your packaging shouldn’t be either. A material that works great for flat-packed clothing won’t cut it for delicate glassware or heavy electronics. The right choice depends on size, weight, fragility, and the kind of unboxing experience you want to deliver. Get this part right, and you’ll protect your products, delight your customers, and keep your costs in check.

For Fragile or Heavy Items

We recommend using corrugated mailer boxes with thicker walls like B-flute or even double-wall board when you’re shipping fragile items or anything with serious weight behind it. These boxes offer the crush resistance and durability needed to keep things safe during transit. To go one step further, add cushioning material like foam inserts, kraft paper, or padded dividers to absorb shock and prevent movement. If you’re dealing with heavy items, make sure the bottom panel is reinforced and that the flaps lock in place securely to avoid box blowouts during handling.

For Clothing or Soft Goods

For apparel, accessories, and other individual items that aren’t breakable, we recommend going with a lighter mailer box made from standard cardboard boxes. These are easier to store, offer easy assembly, and more affordable to ship, and don’t require the heavy-duty protection that fragile products need. To improve the experience, use tissue paper for a neat presentation and minimal void fill to keep everything from sliding around. It keeps the packaging slim, clean, and easy to open—perfect for DTC brands looking to impress without overcomplicating things.

For Premium or Gift Packaging

When presentation is everything, gift boxes made from rigid or specialty board are the way to go. We recommend premium finishes like foil stamping, gloss coating, or embossing to create that high-end feel your customers expect. These materials support your brand identity by turning packaging into an extension of the product itself. If you’re sending influencer kits, luxury items, or special editions, investing in premium packaging helps you leave a strong impression that sticks long after the unboxing.

Important Tips Before Choosing Your Material

Before you lock in your mailer box material, it’s worth stepping back to consider a few practical choices that can impact cost, protection, and presentation. These tips help you avoid common mistakes and fine-tune your packaging setup:

- Use custom sizes whenever possible. A well-fitted box reduces the need for void fill, keeps items from shifting in transit, and helps cut down on overall shipping costs. Plus, carriers often charge based on dimensional weight, so extra space equals extra fees. Don’t overlook other shipping materials like branded tape, eco-friendly void fill, and weather-resistant labels because they all contribute to a stronger and more cohesive packaging system.

- Factor in transit time and environmental conditions. If your products travel long distances or face rough handling, heat, or moisture, go for materials that are durable and can withstand pressure. Corrugated boards, protective coatings, and reinforced seals offer better resilience when the route isn’t smooth.

- Start with free shipping supplies if your business is still testing the waters. Carriers like USPS, UPS, and FedEx offer standard white boxes and envelopes at no cost for account holders. It’s a budget-friendly way to ship while you figure out your permanent solution.

- Don’t forget the tape. Even if your mailer box comes with interlocking flaps or ships flat, you’ll still need quality adhesive for sealing outer cartons, bundling materials, or reinforcing edges when needed.

- Test and scale. Run a few shipments using your chosen material and adjust based on feedback. What looks great on day one might show wear after week two. A little experimentation goes a long way in finding the right setup for your product and shipping workflow.

On A Final Note:

Choosing the right mailer box starts with understanding how each option looks, feels, and performs. If you’re unsure which material best fits your product, shipping needs, or budget, we’re here to help.

And if you’re focused on presentation, protection, or long-term shipping costs, we’ll guide you toward the perfect combination of quality, structure, and design. You can request a free material sample to see and feel your options firsthand or get a custom quote for your next run of packaging boxes.

Every material choice should balance visual appeal with function, offering protection without driving up costs or slowing down your shipping workflow.

Make sure you test before you invest. See how your box holds up in real-world conditions. Confirm that the texture, thickness, and finish match your brand’s expectations.

Ready to make smarter packaging decisions? Contact PackWo today.